Shop Floor Control

Superior functionality makes viewing order information and production reports effortless

In enterprise-level print and packaging environments, gaining total control of the production floor is critical to meeting delivery deadlines, maximizing output, and reducing costly errors. DynamicsPrint® Shop Floor Control is purpose-built for large-scale operations, delivering real-time insights and streamlined workflows to elevate operational efficiency at every touchpoint.

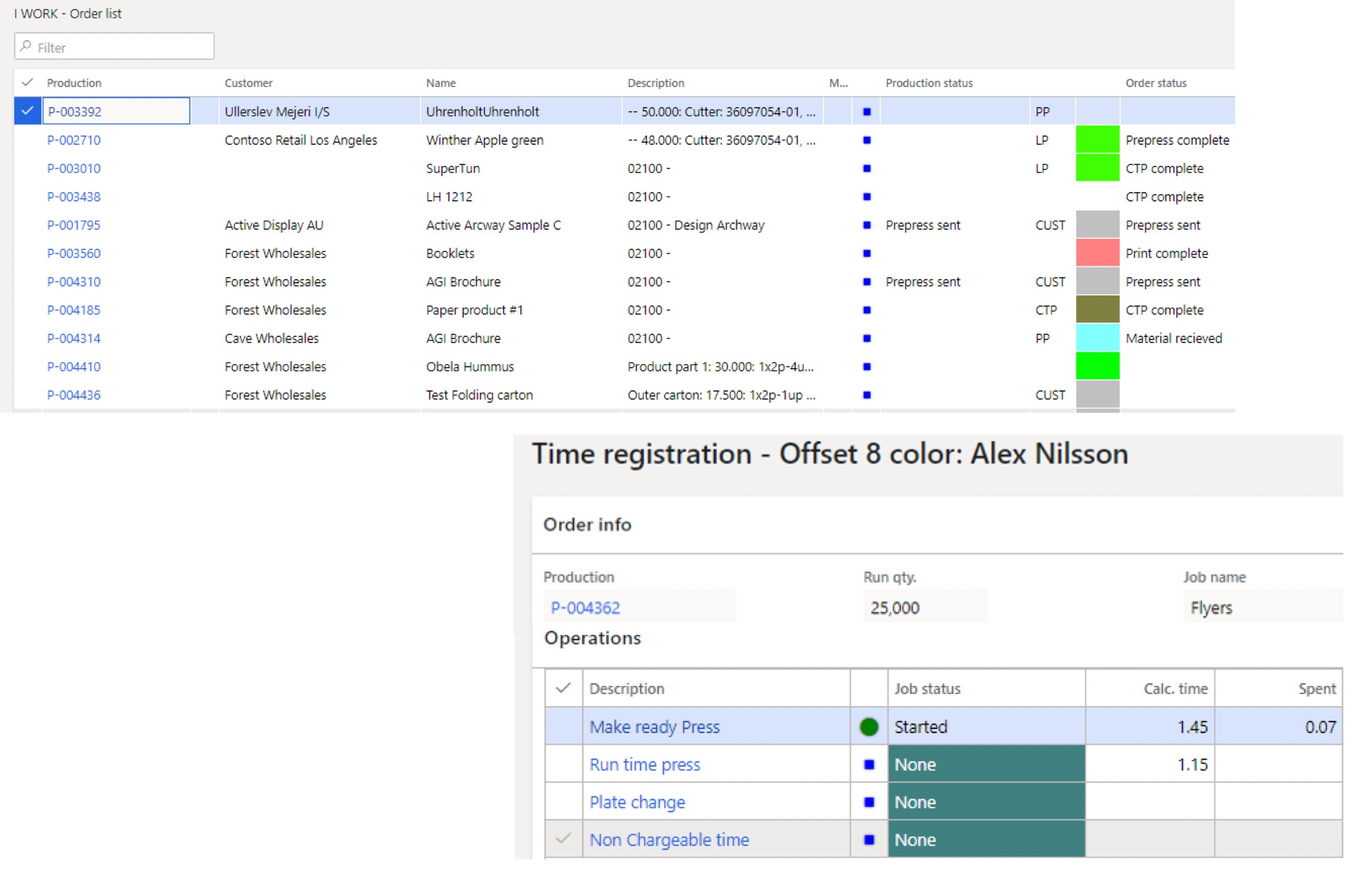

DynamicsPrint® features a modern, intuitive, and fully paperless shop-floor interface that enables seamless registration and tracking of operations. From digital job tickets to real-time updates on job progress, the system empowers machine operators, production managers, and planners to execute flawlessly — without friction.

Whether you manage a single high-volume plant or a global network of production sites, DynamicsPrint® adapts to your structure and scale with role-based views and smart filtering across resources, operators, and jobs.

Book Demo

Digital Job Overview

Operators gain instant access to scheduled tasks for each work center, detailed job specifications, production notes, attached files (e.g., Word docs, images), and internal communication — all within one click.

Time and Material Registration

Start/Stop functionality ensures accurate, secure reporting of time and material usage. Data is automatically posted to accounting as “Work in Progress,” minimizing manual overhead and human error.

Multiple Job Registration

Operators can track time across multiple jobs concurrently, optimizing efficiency without compromising accuracy.

Job Ticket & Job Plans

Every job ticket includes comprehensive specifications and scheduling. Operators can monitor and, if authorized, reschedule operations based on real-time conditions.

Job Routing & Status Tracking

Get a clear upstream/downstream view of each process. Real-time status updates provide a live picture of the entire production floor — perfect for ensuring service-level compliance and operational agility.

Process Flow & Reporting

Generate detailed reports such as pallet notes and transfer instructions with ease, supporting logistics teams with the information they need to maintain flow.

Budget vs. Actual Cost Control

Automatically compare reported resource usage with planned job data to identify deviations, reduce waste, and improve cost accuracy.

Every action on the shop floor is reflected instantly across the ERP environment. Planners see job progress, supply chain managers receive alerts when materials are needed, and customer service teams can update clients with confidence. This unified visibility empowers all stakeholders to make proactive, data-informed decisions.

Do you have any questions regarding DynamicsPrint®?

FAQ

What is the Shop Floor Control module in DynamicsPrint®?

The Shop Floor Control module is a real-time, digital interface for production execution. It gives operators, planners, and managers complete visibility and control over ongoing jobs, materials, machines, and production workflows — from any device.

How does it improve production visibility?

Operators can access job tickets, digital work instructions, job plans, and time/material consumption in real time. Every action on the floor is reflected instantly across the ERP, enabling data-driven decisions across the company.

Can operators record job progress and material usage directly?

Yes. Operators can start/stop jobs, register time, and input material usage through an intuitive digital interface. These actions are automatically posted to the cost accounting system, supporting accurate WIP tracking and budget vs. actual analysis.

Is the interface configurable by user role?

Absolutely. The system supports user-based views and permissions. You can customize visible columns, resource filters, and workflows based on role, ensuring relevant information is shown to each operator, supervisor, or planner.

How does Shop Floor Control support multiple job management?

Operators can register time for multiple jobs simultaneously, which is ideal for departments where machines or resources handle parallel tasks. The system splits and attributes time intelligently, ensuring precise job costing.

Does it support digital and paperless operations?

Yes. Job tickets, setup instructions, images, and communications are all available digitally in one interface, enabling fully paperless production. This not only reduces waste but also improves communication and compliance.

How does Shop Floor Control help improve efficiency?

With live updates on job statuses, bottlenecks, and task completion, planners can proactively intervene. Customer service and supply chain teams also benefit from accurate timelines and production forecasts.

Is it integrated with other modules?

Yes. Shop Floor Control is tightly connected with Scheduling, Inventory, Estimation, and Analytics. Actions from the shop floor automatically update job timelines, material levels, and cost records in real-time.

Can it handle JDF/JMF integration for machine data?

Yes. The module integrates with JDF/JMF-compliant systems, allowing automatic status updates, press feedback, and material tracking from machines like Heidelberg, Kodak Prinergy, Esko, and Agfa.

What measurable benefits can I expect?

Enterprises using Shop Floor Control report higher machine utilization, fewer delays, and enhanced cost control. It enables a more agile, transparent, and accountable production environment that scales with your operations.